Facilities

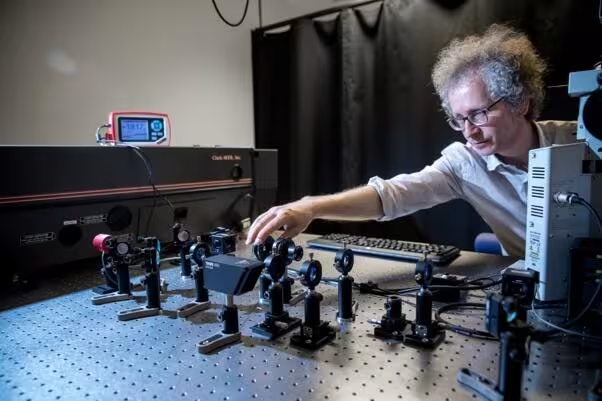

The Fluid Inclusion Lab is located in the Earth Science Department at the University of Bergen (room 2156). The lab is dedicated to microthermometric analyses of monophase liquid fluid inclusions in speleothems and other low-temperature minerals. The lab is equipped with a CPA-2101 amplified femtosecond laser system (Clark-MXR, Inc) which provides single ultrashort laser pulses for stimulating vapor bubble nucleation in metastable, monophase liquid inclusions. The laser is coupled to three microthermometry workstations, each consisting of an Olympus microscope, a Linkam heating/cooling stage and a digital camera. The microscopes are equipped with 100x long working distance objectives (Olympus LMPLFLN 100/0.8).

For more information, please watch our tutorial video Lab setup (external link).

In addition, a camera stand equipped with a Nikon Z50 and 60 mm macro-objective is available to take high-quality overview images of entire thick-sections in transmitted plane polarized light using a LED flat light panel for illumination. A rotatable analyzer mounted on the camera objective allows to image the stalagmite sections under crossed polarizers to study the crystal fabric.

Method

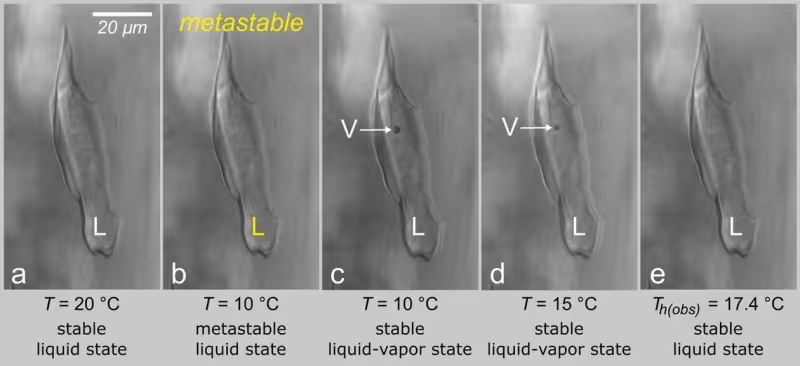

Fluid inclusion microthermometry is a classical technique to assess mineral formation temperatures based on the liquid-vapor homogenization temperature of the inclusions. Fluid inclusions in stalagmites, however, are typically monophase liquid and spontaneous nucleation of the vapor bubble fails to occur upon cooling due to long-lived metastability of the liquid state of water — a fact that previously made microthermometric analyses of these inclusions impossible.

To overcome the metastable phase state, we apply single ultra-short laser pulses to stimulate vapour bubble nucleation. Upon subsequent heating, the liquid water expands while the vapor bubble becomes progressively smaller until it collapses, and the inclusion homogenizes again to the liquid phase. The method is therefore also referred to as nucleation-assisted microthermometry. In order to obtain the correct water density and formation temperature of the stalagmite, we use a thermodynamic model to correct for the effect of surface tension on the measured homogenization temperature (please watch our tutorial video Theoretical background (external link))

Ideally, one single fluid inclusion would be sufficient to determine the formation temperature of the stalagmite, i.e., the cave temperature at a given point in time. In reality, however, we observe a systematic scatter of temperatures derived from different fluid inclusions within the same growth bands. For this reason, we analyze about 40 fluid inclusions to obtain sound statistics for determining one single cave temperature. The precision of the reconstructed cave temperatures is excellent with standard errors of the mean (2SEM) between 0.2 and 0.5 °C.

Sample Preparation

For microthermometric analysis of stalagmite fluid inclusions, we prepare sections of 200-300 μm thickness. Sample preparation involves the following steps:

1. The stalagmite is cut in halves parallel to the growth axis, and then a slab of ca. 10 mm thickness cut from one of the two halves. For the cutting we use a diamond wire saw (Well, Model 6500) with a wire thickness of 0.5 mm. The maximum sample length is 300 mm.

2. Using the same saw, cut a 20 mm wide stripe from the slab either on the left- or right-hand side of the central growth axis. This stripe is finally divided into blocks of maximum 40 mm length.

3. The blocks are then attached to standard (28 x 48 mm) microscope glass slides using superglue. Subsequently, the glass slide with the sample block is fixed on a Buehler Isomet low-speed saw equipped with a 0.4 mm thick blade to cut the thick sections.

A first section is commonly prepared for petrographic analysis. The section is cut to a thickness of 500 μm and then ground and polished to a final thickness of 100-200 μm. This section stays on the glass slide. The remaining block is then attached to a new glass slide and a second section that will be used for fluid inclusion microthetrmometry is cut to a thickness of 200-300 μm. The cut faces of this section do not get polished to keep the mechanical stress on the sample at a minimum. The microthermometry section is further cut into 5 mm wide stripes parallel to the growth direction with a small diamond wire saw (Well, Model 3241). After photographic documentation, the section is removed from the glass slide in an acetone bath.

Note: For petrographic sections, the blocks can also be attached to the glass slides with epoxy resin, but curing must proceed at room temperature to avoid stretching of the inclusions.

For more information, please watch our tutorial video Sample selection and preparation (external link).